Avara Foods Ltd, a leading food production company, embarked on an ambitious upgrade project for their existing feed mill facility as part of Phase 2 of their expansion plans. Their goal was to enhance operational efficiency, improve pellet quality, and streamline production processes while minimising downtime.

Avara Foods required the design, supply, and installation of new conditioners for their existing press lines to increase capacity to approximately 18 to 20 metric tonnes per hour. The project had to incorporate a hot start and long-term retention system, delivering improved pellet quality and reduced fines within a strict 6-week shutdown timeframe.

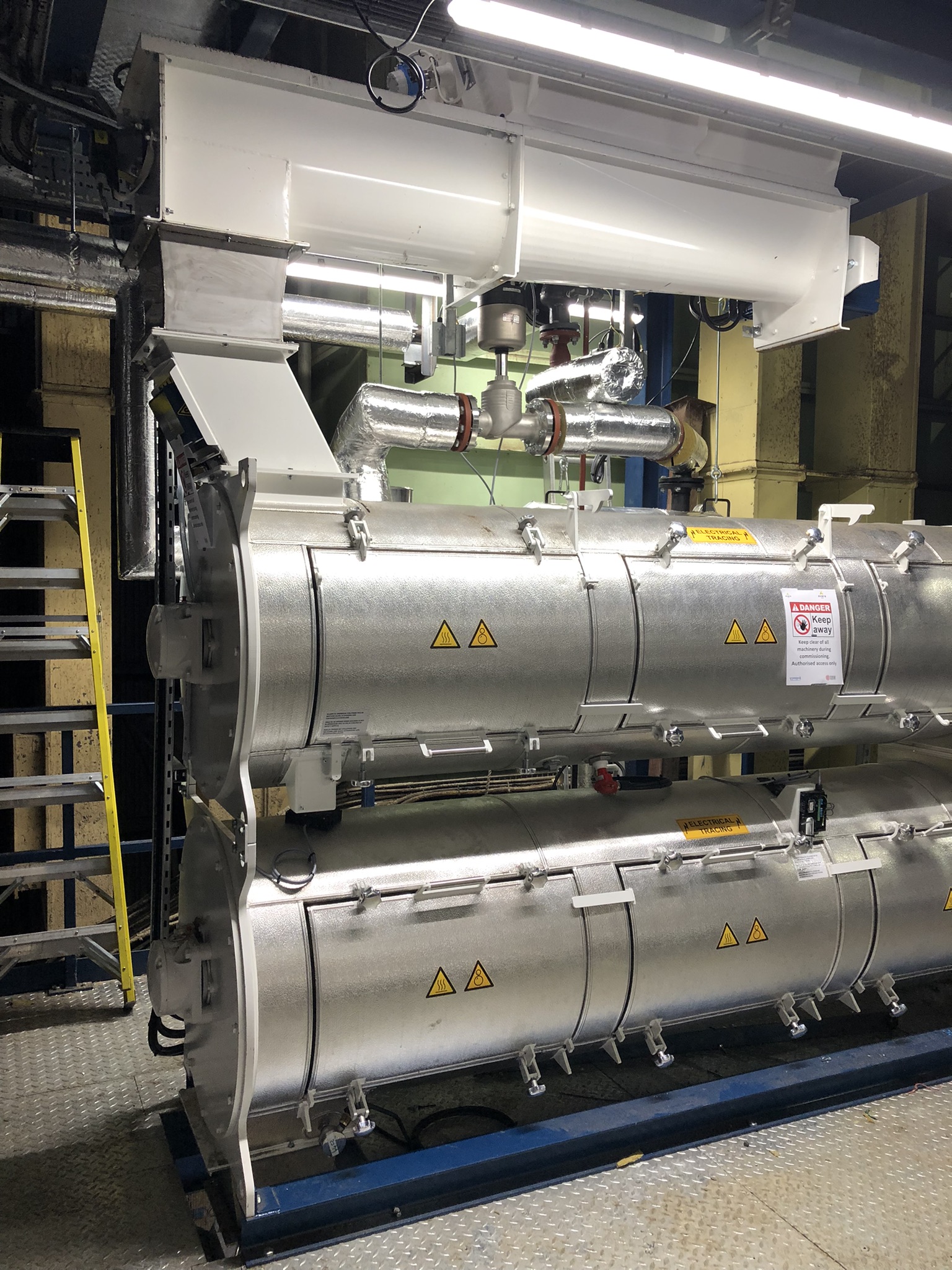

Turner Process Equipment was tasked with extending the press platform and installing new equipment, including PTN Twin Conditioners, feed hoppers, screw dischargers, liquids and steam addition systems, filter units, and control panels. The project involved intricate site work, such as rerouting exhaust ducts, dismantling existing structures, and conducting precise crane lifting operations for equipment installation.

Thorough testing and commissioning were conducted to ensure the new equipment operated at peak performance, with a successful hand-over within the agreed 6-week shutdown period.

With a project value of approximately £750,000 and a duration spanning 10 months from conception to completion, TPE and its partners executed the upgrade efficiently and within budget, meeting Avara Foods’ stringent requirements.

The installation of advanced conditioners and associated systems led to a significant enhancement in production capacity and pellet quality at Avara Foods’ feed mill. The upgraded lines now operate at optimal efficiency, contributing to increased output while maintaining product integrity.

Are you looking to optimize your feed processing capabilities and enhance product quality? Turner Process Equipment offers comprehensive solutions tailored to your specific needs. Whether it’s upgrading existing facilities or designing new processing lines, our team is committed to delivering innovative solutions that maximize efficiency and profitability.

Contact us today to discuss how we can support your project goals and propel your operations to new heights.